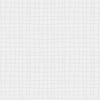

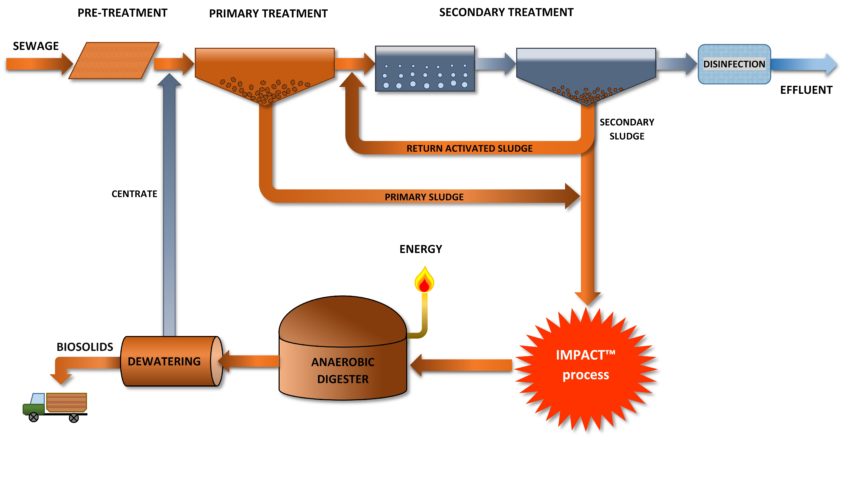

Our company offers a patented process for treatment of sewage sludge and agricultural wastes. It allows municipal wastewater treatment plants to reduce the amount of sludge they generate and significantly lower their operational costs as a result. In a similar manner, the process allows for sustainable manure management in agricultural sector. In addition to cost savings, the process allows for enhanced energy and nutrient recovery from wastewater which can be a source of extra revenue. Our company provides custom process design and works with equipment suppliers and consulting engineers to install and commission the technology for each client.

Boost Environmental Systems Inc. has an exclusive license to use, sell, and sub-license the technology worldwide.